Date:2025-07-29 Views:1001

Materials produced by hot isostatic pressing (HIP) must meet the compositional requirements of ASTM F-799. In the future, titanium-based alloy implants may also be manufactured using the same process. Powder metallurgy can refine grain structure, improve material uniformity, and produce near-net shapes, resulting in high-quality, low-cost implants.

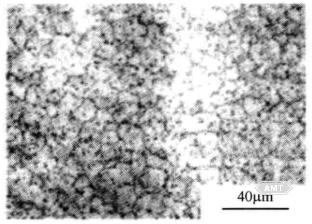

Initially, cobalt-based implants were only manufacturable via investment casting. These alloys exhibited very coarse grains (Figure 10-2) and large carbides, with possible shrinkage pores undetectable by X-ray. Figure 10-3 shows the microstructure of investment-cast Co-Cr alloy.

Figure 10-2 Alloy hip

Figure 10-3 Microstructure of investment-cast Co-Cr alloy

In contrast, materials produced using pre-alloyed powders via HIP have much finer microstructures. The typical microstructure of a cobalt-chromium-molybdenum alloy produced by hot isostatic pressing is shown in Figure 10-4. Each powder particle acts like a small ingot of atomized alloy, resulting in significantly smaller structural features. Carbides are very fine, porosity is eliminated, and grain size is greatly reduced. These changes positively affect mechanical properties.

Figure 10-4 Typical microstructure of a cobalt-chromium-molybdenum alloy produced by hot isostatic pressing

Powder metallurgy enables near-net-shape production. Since orthopedic cobalt-based alloys are difficult to machine, near-net-shape manufacturing is highly desirable.

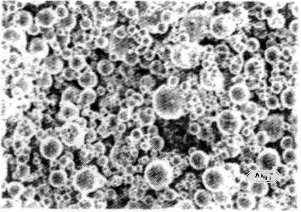

Powders used in implant production must have controlled composition, consistent tap density (to ensure dimensional consistency in fixed-die cavities), and high purity. All orthopedic implants currently produced via powder metallurgy use inert gas atomized powders. Suppliers must follow the same precautions and storage/transport methods used in aerospace applications. Figure 10-5 shows typical inert gas atomized Co-Cr-Mo powder——spherical in shape, with smaller "satellite" particles adhering to larger ones.

Figure 10-5 Typical inert-gas-atomized Co-Cr-Mo powder (180×)

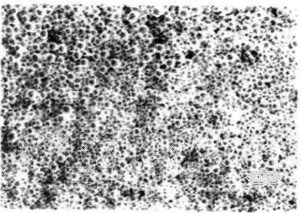

Another method is the plasma rotating electrode process (PREP), which produces smoother, more spherical powders (Figure 10-6). PREP powders are being considered for implant use, but adoption depends on cost.

Figure 10-6 SEM micrograph of a cobalt-chromium-molybdenum alloy produced from powder manufactured by the plasma rotating electrode process(20×)

All dense powder metallurgy parts to date have been produced using an alternative to HIP. Rapid omnidirectional pressing uses a thick-walled metal can (steel or non-ferrous) with a pre-formed cavity. The can is filled with powder, sealed, heated, and pressed in a conventional press. The metal can applies quasi-isostatic pressure, making this method attractive for producers without HIP equipment.

The resulting microstructure (Figure 10-7) is similar to HIP-produced material, and mechanical properties are comparable.

Figure 10-7 Microstructure of a cobalt-chromium-molybdenum alloy manufactured by rapid omnidirectional pressing

The process is similar to HIP of nickel-based superalloys in aerospace. Inert gas atomized powder is loaded into a metal can, vacuum-sealed, and HIP-processed. After can removal, the preform is forged to final dimensions. Typical parameters: 1100℃, 100 MPa, 1 hour.

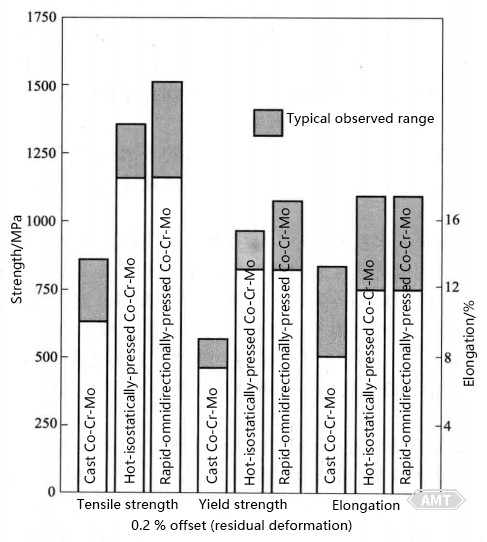

Compared to cast cobalt-based alloys, powder metallurgy-produced Co-based alloys have much finer microstructures and significantly improved mechanical properties. Figure 10-8 compares tensile properties of ASTM F75 Co-Cr-Mo alloy produced by casting, HIP, and rapid omnidirectional pressing. All static properties are superior for powder metallurgy parts.

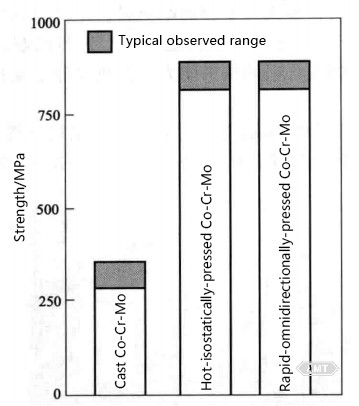

Figure 10-9 shows the 10⁷-cycle rotating-beam fatigue endurance limit. Powder metallurgy parts have twice the fatigue strength of cast materials. Fatigue strength is critical for medical devices, so this improvement is highly beneficial.

Figure 10-8 Tensile properties of Co-Cr-Mo alloy

Figure 10-9 10⁷-cycle rotating-beam fatigue endurance limit of Co-Cr-Mo alloy

Corrosion behavior of ASTM F75 Co-based alloys depends mainly on matrix composition. Different microstructures have similar corrosion resistance. Cast and powder metallurgy Co-Cr-Mo alloys show identical electrostatic potential corrosion curves, including rest potential, passivation, and pitting potential. Both investment-cast and powder metallurgy Co-Cr-Mo alloys have proven corrosion-resistant in the human body.

Leave your email for more ebooks and prices📫 !

Contact:Fidel

Tel:021-5512-8901

Mobile:19916725893

Email:sales7@atmsh.com

Address:No.398 Guiyang Road Yangpu China