Date:2025-05-27 Views:1029

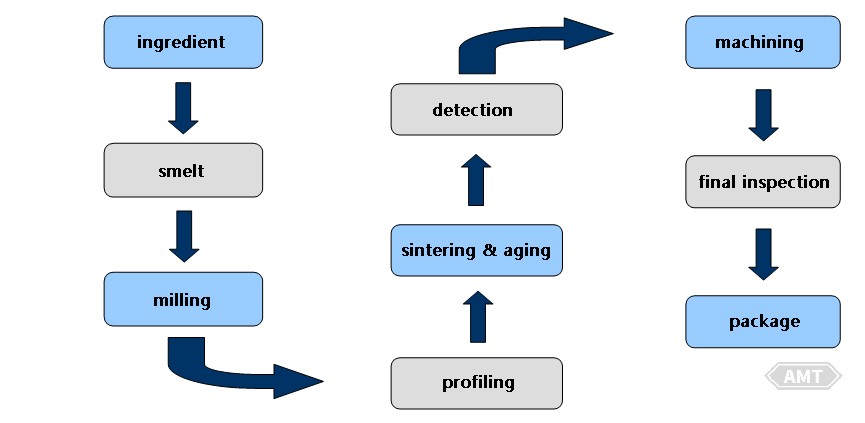

Samarium cobalt magnets are primarily made from samarium, cobalt, and other metals. These materials are blended in specific ratios and undergo processes like high-temperature melting, powder making, pressing, and sintering to form various grades of blanks. Then, based on users' required properties, selected blanks are machined into desired shapes and finally magnetized.

We produce a series of sintered samarium cobalt products in various shapes and performance levels. Our advantages include:

Maximum size for a square block is 130mm×130mm×100mm, achieving full magnetic saturation

Mass production of high-grade YXG-33H samarium cobalt products with a (BH)max of 30-33MGOe

Mass production of samarium cobalt products with HK≥18KOe, featuring high HK and stability

Production of planar multi-pole samarium cobalt products with a magnetizing thickness limit of generally 6mm

Mass production of 1:5 pure samarium cobalt products

Mass production of large-size radially magnetized magnet components for magnetic levitation high-speed motors and magnetic levitation blowers

Customization of samarium cobalt magnets to users' special performance requirements and continuous development of new grades

Production of products where the deviation between the magnetizing direction and the mechanical axis is within 1° (for magnetized products)

Customization of ultra-high magnetic energy product YXG-35 samarium cobalt products: Br reaches 11.6-12kGs, and (BH)max reaches 32-35MGOe

Customization of ultra-low temperature coefficient LTC(YXG-18) samarium cobalt products: Under RT-100℃, the Br temperature coefficient is -0.001%/℃

Customization of high-temperature resistant HT500 samarium cobalt products, which can operate up to 500℃

Production of various complex-shaped and multi-angularly magnetized samarium cobalt magnet assemblies, such as Halbach arrays

Since our establishment, through continuous investment and development, we have become a leading enterprise in China's samarium cobalt industry. Our customers are worldwide, and many large companies from various countries have adopted our products, which are widely used in aerospace, rail transportation, high-temperature motors, microwave devices, magnetic power transmission, etc. We welcome new and old customers to consult and cooperate!

Conventional size and shape: Conventional Sizes and Shapes Schematic.pdf

Among the three dimensions noted above, only one or two maximum dimensions can be produced. M represents the magnetizing direction. Due to the extreme brittleness of samarium cobalt materials, the thickness of products with large outer diameters or large square sizes can't be too thin. Also, the walls of large annular products can't be too thin. The above introduces conventional-shaped products. Our company can also produce samarium cobalt products in various other shapes. Feel free to inquire with drawings.

When multiple direction dimensions are required to be large, our company's special splicing process can be adopted.

Due to the extreme brittleness of samarium cobalt materials, the thickness of products with large outer diameters or large square sizes can't be too thin, and the walls of large annular products also can't be too thin. Specific requirements should be determined based on factors such as drawings, shapes, and magnetizing directions.

When inquiring about prices, please provide detailed information such as dimensions, tolerances, performance grades, quantities, whether electroplating is needed, magnetizing methods, and other special requirements. For non-standard products, drawings should also be provided.

Leave your email for more ebooks and prices📫 !

Contact:Fidel

Tel:021-5512-8901

Mobile:19916725893

Email:sales7@atmsh.com

Address:No.398 Guiyang Road Yangpu China