Welcome~AMT Advanced Metal Material Technologies ( Shanghai ) Company Limited

Date:2025-07-31 Views:0

Guide and control melt flow

Prevent backflow

Manage filling speed and pattern

Influence part strength and sintering behavior

Affect final part appearance (gate vestige)

| Type | Pros | Cons | Best For |

|---|---|---|---|

| Direct Gate | Low pressure loss; good for thick parts | Large vestige; high stress | Large structural parts |

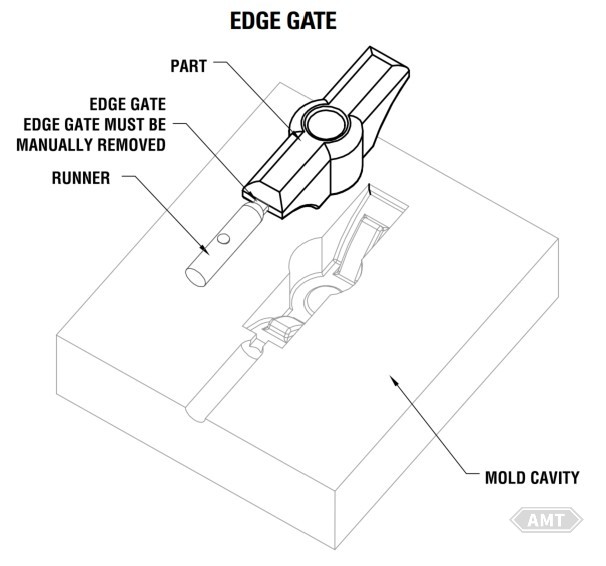

| Edge Gate | Simple; adjustable; easy removal | Visible side marks | Flat/box-shaped parts |

| Point Gate | Small marks; auto-removal possible | Complex mold; high shear | Small, high-precision parts |

| Ring Gate | Uniform filling; no weld lines | Hard to remove; wasteful | High-roundness tubes |

Manual: Knives, pliers (low cost, inconsistent)

Mechanical: Punching dies (fast, precise)

Machining: Milling/grinding (high accuracy)

Laser: Non-contact, precise (expensive)

Tumbling: Post-removal polishing

Use self-removing gates (point/undercut gates)

Place gates in hidden/thick areas

Optimize size (small but functional)

Add break points for clean removal

Avoid stress zones

Leave your email for more ebooks and prices📫 !

Contact:Fidel

Tel:021-5512-8901

Mobile:19916725893

Email:sales7@atmsh.com

Address:No.398 Guiyang Road Yangpu China