Date:2025-05-30 Views:1011

AMT has long collaborated with renowned domestic research institutes and universities. It delves into application-related issues of soft magnetic products, continuously improving them, and owns independent intellectual property rights.

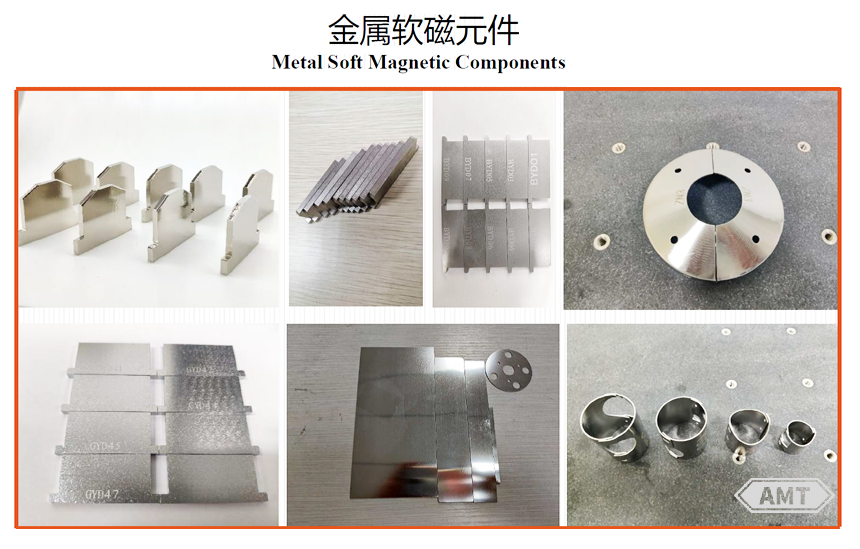

The Soft Magnetic Division uses high-quality soft magnetic metals like electromagnetic pure iron, cobalt-vanadium iron, and permalloy as raw materials. It specializes in making various soft magnetic components and precision assemblies, such as pole-shoe magnetic yokes, transformer cores, magnetic pole heads, inductor cores, and magnetic shields, and also deals in ferrite cores.

This division aims to satisfy domestic and international clients in fields like electrical engineering, electronics, precision measurement, scientific research, and high-energy physics by supplying top-notch soft magnetic products. It also offers comprehensive solutions, including magnetic field physics design, product structure optimization, and technical support.

Electromagnetic pure iron, a superior special magnetic steel with over 99.5% iron content, boasts the following tech features:

Low coercivity Hc, high permeability μ, and high saturation magnetization Bs. It's ideal for scenarios demanding high magnetic flux density under static low-field and low-frequency conditions but isn't suitable for high-frequency applications due to its low resistivity.

High purity, dense structure, and uniform microstructure. The gas content in electromagnetic pure iron relates to its density. Gas-free and crack-free pure iron meets the stringent vacuum and magnetic stability requirements of certain fields. However, uncoated electromagnetic pure iron products have poor corrosion resistance and usually need protective coatings.

Good machinability allows for various mechanical processes like turning, punching, bending, and welding. The surface quality of machined components is fine, yet the material's softness requires precautions against mechanical scratches during production, quality inspection, transportation, and installation.

Electromagnetic pure iron products find broad application in fields like iron cores, electromagnets, permanent-magnet motors, DC motors, magnetic powder clutches, electrical equipment, car engines, magnetic shielding, instruments, electronic components, electromagnetic valves, magnetic separators, medical imaging, telecom equipment, power generation, aerospace, and accelerators.

Cobalt-vanadium soft magnetic materials mainly consist of cobalt and iron, which are costly. Their key tech features are:

The highest saturation magnetization Bs among current soft magnetic alloys at 2.4T, a high Curie temperature Tc, and the largest saturated magnetostrictive coefficient (e.g., 1J22 reaches 60~100×10 - 6).

The high Bs enables miniaturization of electromagnetic devices with equivalent power. The high Tc ensures good magnetic stability at elevated temperatures, and the large magnetostrictive coefficient suits transducers, boosting output energy and efficiency.

Low resistivity and high eddy current losses make them unsuitable for high-frequency use. Adding appropriate Ni, V, or other elements enhances processability and oxidation resistance, but most applications require coating protection.

Cobalt-vanadium iron alloy-made components are widely used in fields demanding miniaturization and high-temperature operation, such as aviation electrical systems, micro motors, electromagnets, relays, and motors. Domestic grades include 1J21, 1J22, and 1J27.

Permalloy refers to Ni-Fe alloys with adjustable nickel content from 30% to 90%. It's a high-performance metal soft magnetic alloy with broad applications. Its main tech features are:

High permeability, low loss, and a small magnetostrictive coefficient. Inductors made from it have strong anti-saturation capability, high inductance, good stability, compact size, and are energy-saving and efficient.

Good processability ensures fine surface quality of components and excellent weldability. However, as permalloy's magnetic properties, especially permeability, are sensitive to mechanical stress, products shouldn't be knocked or bent after annealing, and application-related installation stress should be minimized.

With a high nickel content, permalloy has good general-environment corrosion resistance, especially high-nickel perm alloys, which usually don't need special rust-proof treatments like coating.

There are many permalloy grades, categorized into four groups based on composition: 35%~40% NiFe, 45%~50% NiFe, 50%~65% NiFe, and 70%~81% NiFe alloys. Each group's hysteresis loop state can be adjusted via process parameters, offering flexible choices for users.

Common permalloy grades are 1J50, 1J79, and 1J85. 1J50 has slightly lower saturation magnetization than silicon steel but dozens of times higher permeability and 2-3 times lower iron loss, making it suitable for transformers with higher power frequency (400-8000Hz). 1J79, with good overall performance, fits high-frequency, low-voltage scenarios. 1J85 has an initial permeability exceeding one hundred thousand, ideal for weak-signal, low-frequency, or high-frequency applications.

Low-temperature permalloy 1JL0 stands out for its high magnetic performance, especially permeability, under extremely low temperatures like below 2-77 K. Its initial permeability stays above 20,000 and can exceed 50,000 after special preparation and cyclic annealing. It's perfect for ultra-low-temperature scenarios like large-precision magnetic shielding components in synchrotron radiation and free-electron laser superconducting cavities. In contrast, 1J79 and 1J85 would see a significant permeability drop in such cold conditions.

Permalloy is widely used in electronic communication, precision measurement, rectifier devices, magnetic shielding components, relays, transformers, mutual inductors, and electromagnetic clutches.

Soft magnetic ferrites, non-metallic ferromagnetic materials mainly composed of Fe2O3, include MnZn and NiZn types. They're divided into three application-oriented categories: telecom ferrites, broadband and EMI ferrites, and power-type ferrites. Compared to other metal soft magnetic materials, non-metallic soft magnetic ferrites have the following key tech features:

High resistivity, hundreds to hundreds of thousands of times higher than general metal soft magnets, makes them suitable for medium- and high-frequency applications.

Without using scarce materials like nickel, soft magnetic ferrites can achieve high permeability. Their ceramic-like processes enable mass production at low cost and are insensitive to stress, with relatively stable permeability across frequencies.

However, soft magnetic ferrites have drawbacks like low saturation flux density, low permeability, and low Curie temperature, limiting their application scope, though efforts are ongoing to improve these aspects.

They're widely applied in fields like electromagnetic interference suppression, electromagnetic compatibility, electronic countermeasures, automated control, aviation and aerospace, computer and information technology, automotive and transportation, consumer electronics, and lighting systems.

Leave your email for more ebooks and prices📫 !

Contact:Fidel

Tel:021-5512-8901

Mobile:19916725893

Email:sales7@atmsh.com

Address:No.398 Guiyang Road Yangpu China