With 10+ kinds of metal forming process, which can efficiently meet the rapid prototyping and mass production of industrial components.

Advanced equipment · Professional personnel · Refined management · Rich experience

• 50 years of metal forming experience, 20+ senior engineers with over 10 years of expertise

• Services include technical consultation, drawing pre-review, structural analysis, risk assessment, constructive design suggestions, and cost analysis

• Mature quotation system: 8 sales engineers provide online quotations within 30 minutes to 2 hours, 8:00-24:00

• Processed 475 materials, verified by spectrometer for authenticity

• 21 surface treatment processes, 8 patented tooling fixtures

• 100+ all kinds of processing equipment, 24-hour shift, 300000㎡ workshop • Dynamic milling technology improves rough machining efficiency by 50% • Stable workforce: 568 employees, 90% with over 15 years of experience • Sales and follow-up staff all undergo 3+ years of training and certification, with dedicated project follow-up • CNC/Rapid prototype 1-10pcs: 1-5 days; 100-1000pcs: 7-15 days ;mass production within 50k: 45 days

• Engineers pre-review drawings, focusing on precision and assembly, to formulate processing plans • Original imported CNC equipment with BT spindle, surface finish Ra1.6, tolerance ±0.005mm • Expertise in complex workpieces, custom fixtures and jigs available for projects • 21 types of inspection equipment including automatic CMM, 2D measuring instrument, height gauge • Each product undergoes at least 4 full inspection processes • Certified to ISO9001:2015 quality management system

• Zhuanxin Precision's unique diversified custom processing = 475 materials × 28 processing techniques × 21 surface treatments × custom packaging • 3 free policies: free process consultation, free modification, free sampling • 3021 after-sales rule: 30-min response, 2-hr solution, 1-day resolution • New customer follow-up within 3 days, quarterly customer satisfaction surveys for continuous improvement

To begin, you simply choose the manufacturing process and upload your design files.

Within a few hours, a design for manufacturability analysis will be completed for you.

Foucs On All Kinds of Metal Forming Serivces For Prototyping & Mass Production

AMT: Excellence in Metal Forming Solutions Since 1988Founded in 1988, AMT has evolved from a specialist in metal injection molding and magnets to a global leader in integrated metal forming technologies. With eight state - of - the - art production f···

MOREblogs

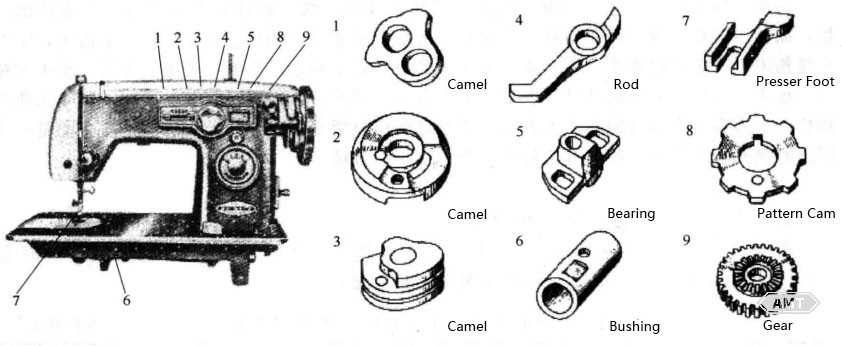

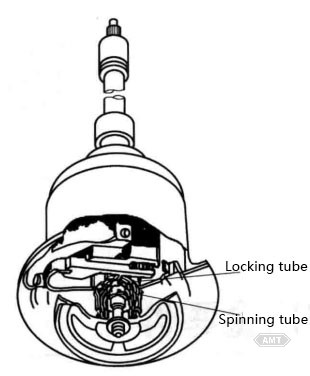

AMT | Powder metallurgy parts in sewing machines

Table of contentsIntroductionInsights from Taiwan's Powder Metallurgy Parts MarketPowder Metallu···

AMT | Powder metallurgy parts in household appliances and machinery

Table of contentsPowder Metallurgy Parts in Household AppliancesPowder Metallurgy Parts in Automatic···

AMT | Powder Metallurgy Components in Manual Transmission Synchronizer Systems

Table of contentsPowder Metallurgy Components in Manual Transmission Synchronizer SystemsPowder Meta···

AMT | Application of Powder Metallurgy Structural Parts in Automotive Manufacturing

Table of ContentsOverviewThe Progress of Conventional Powder Metallurgy Structural Parts in Automobi···

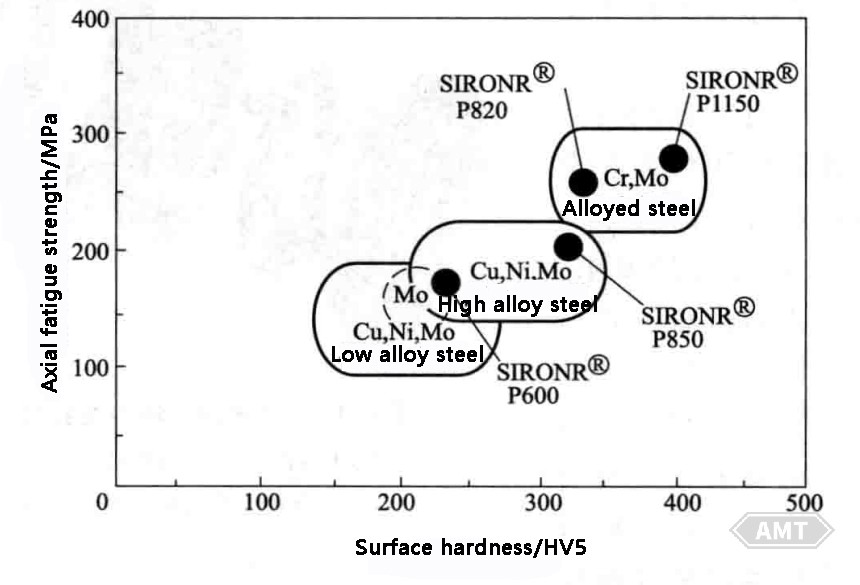

AMT | Comprehensive Guide to Powder Injection Molding Appendices

Table of ContentsCommon Heat Treatments for Sintered PIM AlloysTool Costing CalculationsPart Costing···

AMT | Definitions and Nomenclature in Powder Injection Molding

Table of ContentsJustificationUnits and Conversion FactorsNomenclature and SymbolsDefinitionsJustifi···